Taking a Look Inside: Stator and Rotor

Alright, so the other day I had this old desk fan that finally gave up. Instead of just tossing it, I figured, why not crack it open and see what makes it tick? I’ve always been curious about the actual motor parts, you know, the stator and the rotor everyone talks about.

First thing, I got my screwdriver set out. Taking off the plastic casing was pretty straightforward, just a few screws here and there. Then came the motor housing itself. It was a bit greasy, honestly. Had to wiggle it a bit to get the cover off. Inside, there it was – the heart of the fan.

It was immediately obvious which part was which, even without a manual.

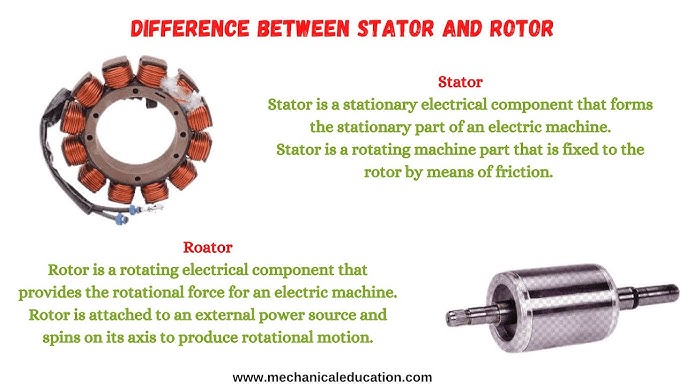

- There was the outer part, fixed solid, with lots of copper wire windings visible. That had to be the stator. It stays put, right? Makes sense.

- And then there was the central piece, the bit attached to the shaft where the fan blades used to be. That spun freely (well, mostly freely, it was an old fan). That’s the rotor.

Getting a Closer Look

I carefully pulled the rotor out from the center of the stator. It slid out fairly easily. The stator was heavier than I expected, mostly because of all that copper wire wrapped around laminated iron sections. Looked like a lot of work went into winding those coils just right. It was bolted securely to the motor frame.

The rotor was interesting too. It wasn’t just a solid chunk of metal. It looked like it was made of thin metal plates stacked together, with what looked like metal bars running through it, angled slightly. No wires on this part, which I sort of remembered is how many simple fan motors work. It felt solid and balanced when I held the shaft.

I spent some time just looking at how the two parts fit together. The gap between the rotor and the stator was really small. I guess it has to be, for the magnetic fields to do their job properly. I slid the rotor back in and gave it a spin with my fingers. Even without power, you could almost feel the interaction, like they were meant to work together.

Putting it back together? Nah, didn’t bother. The fan was kaput anyway. But it was a good hands-on experience just taking it apart and actually seeing the stator and rotor up close, not just in diagrams. Pretty cool seeing how these basic electric motor principles are put into practice in everyday things.