Alright, buckle up, ’cause I’m gonna walk you through this two-stroke engine project I tackled. It was messy, loud, and a total blast.

It all started with this beat-up old two-stroke engine I snagged from a buddy. It was sitting in his garage collecting dust, and he basically gave it to me for a song. I figured, “Why not? Let’s see if I can get this thing running.”

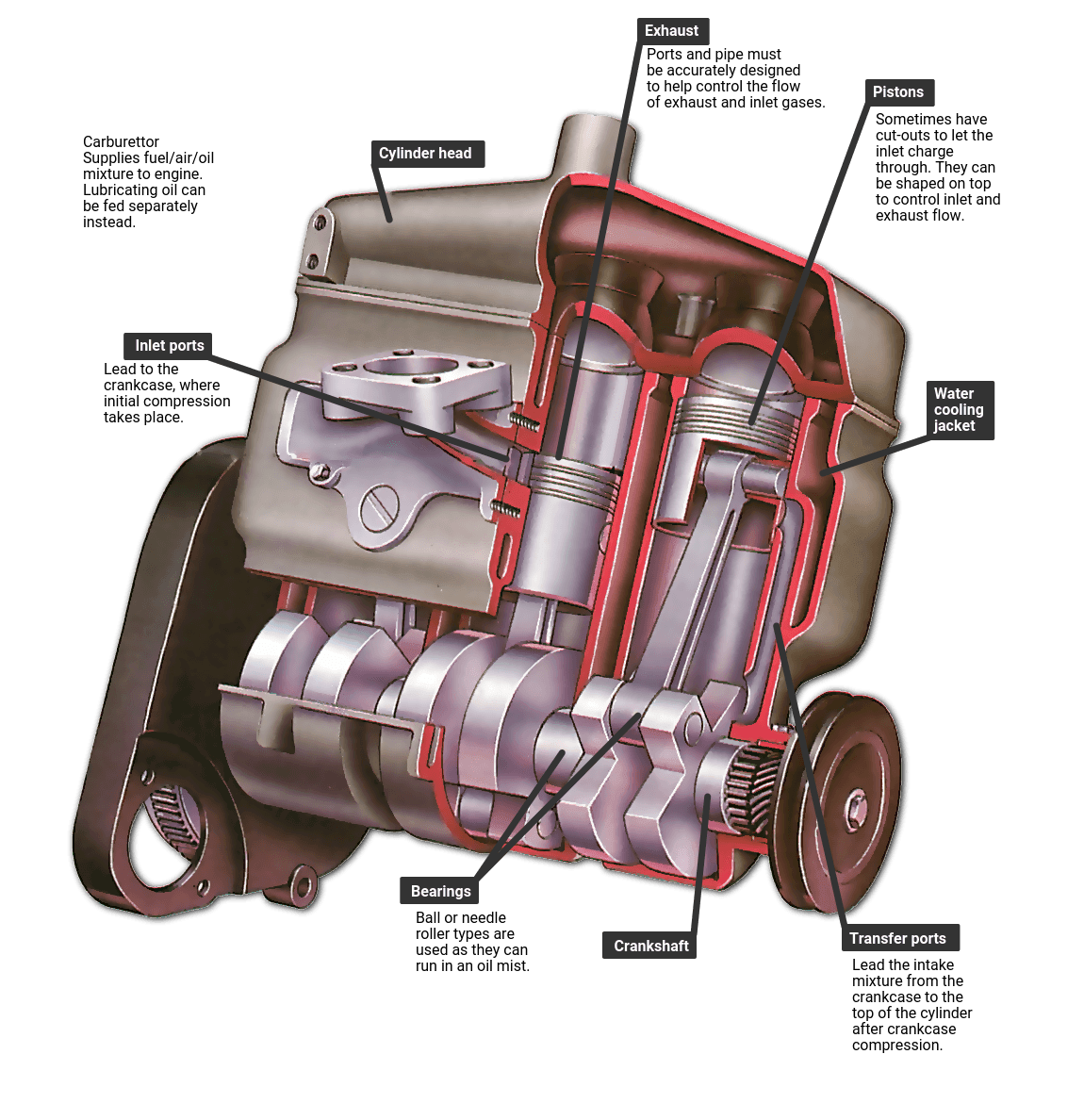

First things first, I ripped the whole thing apart. I mean, completely disassembled it. Everything was covered in grime and old oil. I spent a good chunk of time just cleaning parts. Carburetor was gunked up, piston was coated in carbon, the whole shebang. Used some carb cleaner, some degreaser, and a whole lot of elbow grease.

The fun (and frustrating) part: Figuring out what was actually broken. The piston rings were shot, plain and simple. Ordered a new set online. Also, the spark plug wire was frayed, so I replaced that too. While I was at it, I cleaned up the spark plug itself. Looked like it hadn’t been touched in years.

Once the new parts arrived, I started putting things back together. New piston rings on the piston, cylinder head back on, torqued everything down to spec (important!). I followed a repair manual I found online – a lifesaver, honestly. Wouldn’t have known where to start otherwise.

Next up was the carburetor. I’d taken it completely apart for cleaning, so reassembling it was a bit of a puzzle. There were tiny little jets and needles that had to go in just the right place. Used some compressed air to make sure all the passages were clear.

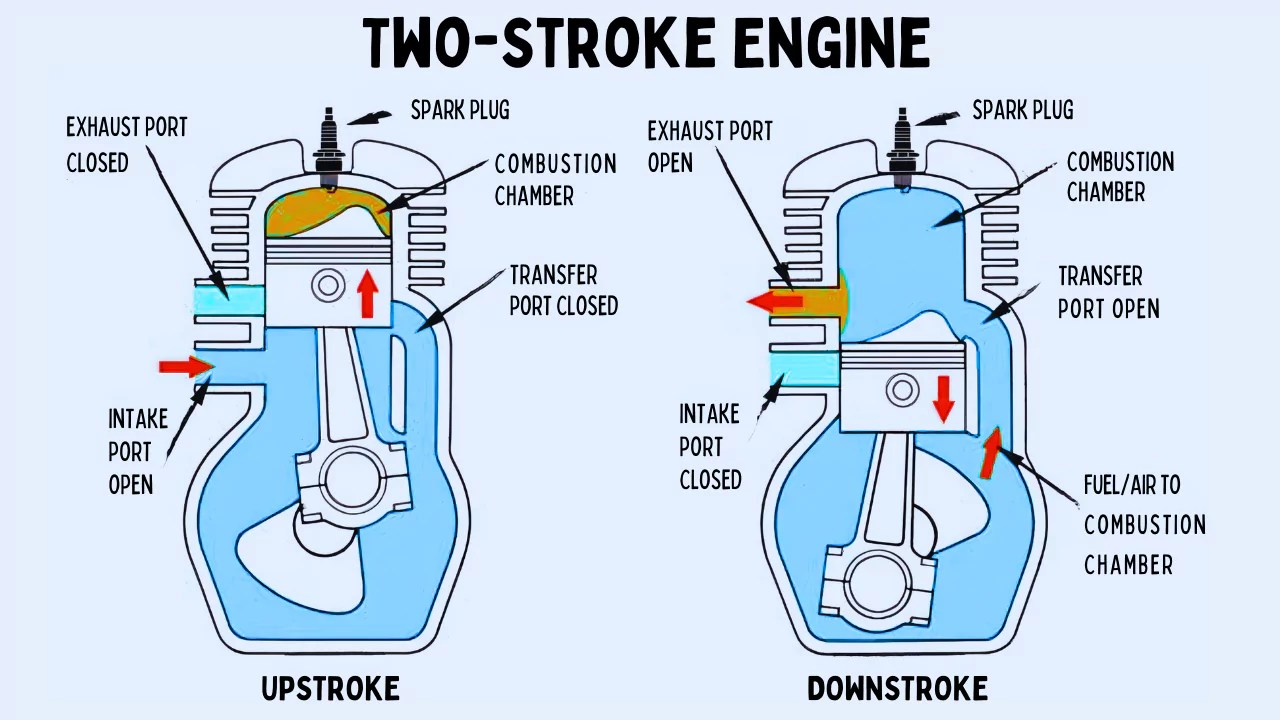

Then came the moment of truth. Hooked up a fuel line, filled the tank with a gas/oil mix (remember, it’s a two-stroke!), and gave the pull cord a yank. Nothing. Yanked it again. Still nothing.

Here’s where the troubleshooting began. I checked for spark. Yep, got spark. Checked the fuel line. Fuel was getting to the carb. Hmmm… Turns out, I had the idle screw on the carb completely wrong. Adjusted that, gave it another yank, and…BRAP! It sputtered to life! Sounded rough as hell, but it was running!

I spent the next hour or so adjusting the carburetor, getting the idle right, and generally tweaking things until it ran smoother. It’s still not perfect, but it’s running reliably. Now I’m figuring out what to do with it. Maybe stick it on a go-kart? Or a mini-bike? The possibilities are endless.

Learnings

- Two-stroke engines are simpler than you think, but they can be finicky.

- Cleanliness is key. Seriously, clean everything.

- A repair manual is your best friend.

- Don’t be afraid to get your hands dirty.

Overall, it was a super satisfying project. Took a dead engine and brought it back to life. Plus, I learned a ton about how these little engines work. Highly recommend giving it a try if you’re looking for a fun and challenging project.